We work in partnership with our clients, delivering packaging solutions according to the various needs our customers have. We draw on our in depth packaging expertise and industry experience, combining development creativity with business acumen and specialized project management skills.

Development

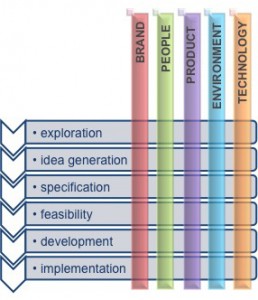

We take a multi dimensional approach at any stage of the packaging development process. From front end needs through to transfer to manufacture.

We take a multi dimensional approach at any stage of the packaging development process. From front end needs through to transfer to manufacture.

Throughout projects we align progress between the different internal and external disciplines, which are involved during the development stages of the project.

3d identity

Developing 3D packaging design (look & feel), which is close to the brand and is outstanding on the shelf. We come to surprising results by stretching the limits of the different packaging technologies, without compromising on costs or production efficiency.

With these projects we team up with design companies in brand and 2D graphic design.

In use functionality

Creating real added value to the consumer by developing easy to use convenient packaging, closures and delivery systems. Based a real understanding of consumer behaviour we develop usage concepts and turn these into highly functional constructions and shapes.

However, even the best concept has to prove that it is ready for high volume production and cost targets can be met. For us at Packaging Intelligence this is the route from art to part.

Sustainable packaging

Developing Eco responsible packaging by using the tools to sift through the ever changing barrage of materials, services, regulations and mandates. Designing green packaging, by applying the principles of re-duce, re-cycle, re-new and re-use, without jeopordizing the basic functionalities of the packaging.

Cost saving (incl. manufacturing efficiency)

Serving brand owners of consumer goods (packed) products, who are under intense price pressure. We start with questioning and reassessing the fundamentals of the packaging specification, the selected technology and its manufacturing process. We develop optimized constructions of the packaging parts and it’s materials, resulting in cheaper components, simplified assemblies and more efficient processing and filling. Additionally, cost saving projects, always lead to significant performance increase.

Product protection

Improving product’s shelf life by selection and development of the most optimal packaging technology and/or materials. This could also involve the development of airless systems to prevent from oxidation of the product.

Secondly we develop transportation proof packaging, which smoothly passes transportation test requirements.

We develop test protocols and perform the testing. We understand how to comply with norms and legislations for the different industry sectors, incl. for food safety and pharmaceutical products.

Delivery and transfer to manufacture

With these projects, we help to find the right packaging supplier and /or contract manufacturer, choose customers tooling strategy and undertake design for assembly and manufacture. Furthermore it is about finding support for prototype trial builds and managing the transition to volume manufacture. With these type of projects we closely cooperate with Verhoeven Ontwerpbureau.